Mineral Fibers - Fiber Glass, Basalt Fiber, Carbon Fiber

Cold Production Process System

CAPP Engineering

Manufactures complete, Automatic Handling Lines for:

- BOBBINS STRIPPING (PEEL OFF)

- SORTING

- BOBBINS PACKAGING

- PALLETZING

- PALLET PACKAGING

- PALLET STORING

The modern solution we adopt, allows us to reach high quality standards and to reduce the waste.

So our automation is:

- Minimum Handling

- The product is untouched and uncontaminated

- Full Tracking

CAPP Engineering

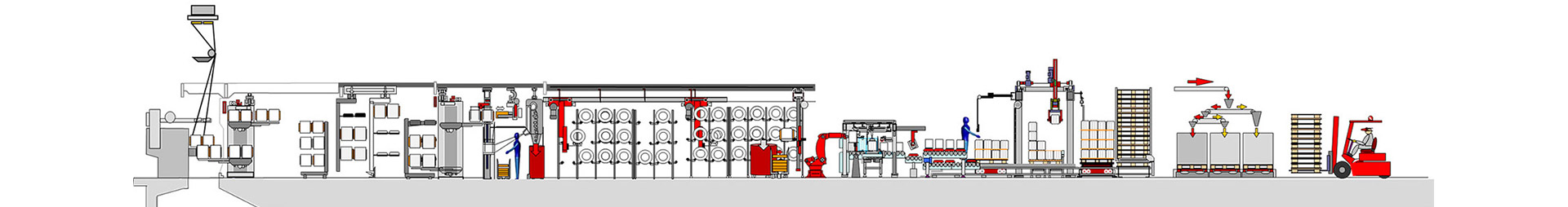

Starting from Bushing to Palletizing Storing and Shipment we realize complete automation systems for the production process with full tracking feature on the FiberGlass fields.

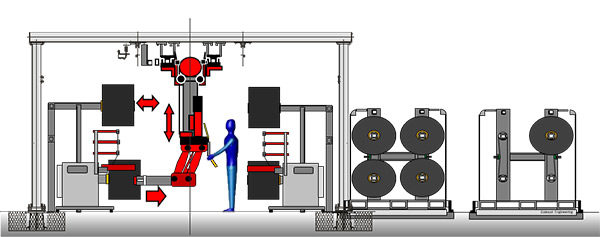

Automatic doffing:

In the winders area special and customized Doffers realize the complete automatic doffing process. Modular Doffer Robots are equipped with mandrels or Telescopic Cradles in order to interface the winders to be served, it doffs the bobbins cake and then it introduces the empty tubes. On board special devices are available for Weighing, Tube dispenser, Trolley interface, etc.. Interfaces are automatic and the robots can work in safety with operators presence. Different forming area layouts are possible.

Automatic Handling:

From the forming area where the bobbins are produced, they are handled to the oven area to be treated for the drying process . Different solutions are possible starting from standard conveying , shuttle, AGV systems.

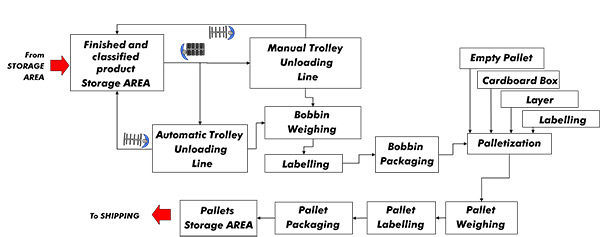

Bobbins Packaging Area:

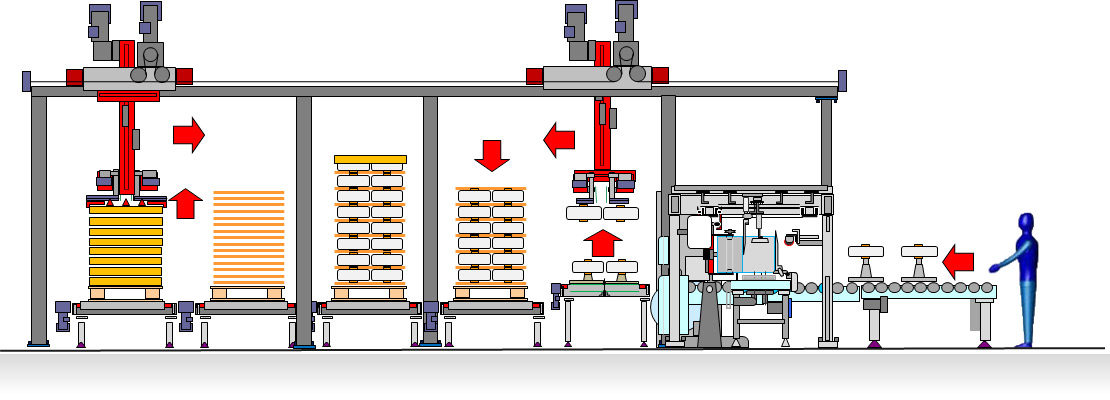

After the drying process the bobbins go to the stripping processes (peel off).

Depending on the type of product (direct or assembled roving) the bobbins are worked without being touched where treated. For the direct roving the packaging is executed in cold process with a tensionless film.

Then the bobbins are palletized, pallets are packaged and stored. All these processes include sorting, weighing and labelling. All in full tracking solution. For the assembled roving cakes, after being stripped are automatically convoyed and loaded to the creels for the rewinding process. Here special doffing robots can automatically execute the doffing, relaunching and the packaging of the assembled roving bobbins.

Then palletizing with knotting station, pallet packaging and storing. All in full tracking solution.

FiberGlass Creel and Stripping Area - Typical Layout

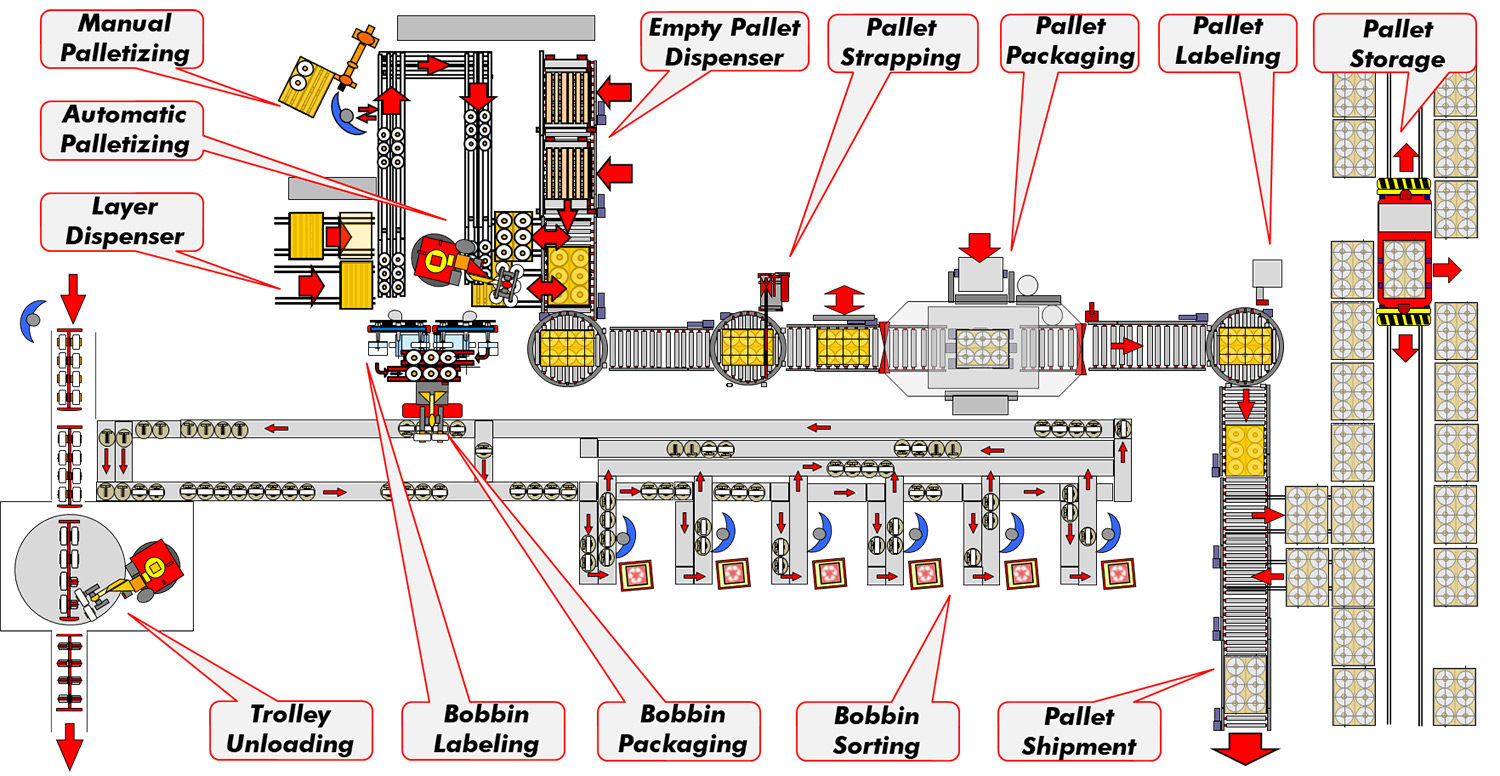

FiberGlass Packaging Area - Typical Layout

Mineral Fibers - Carbon Fiber

Cold Production Process System

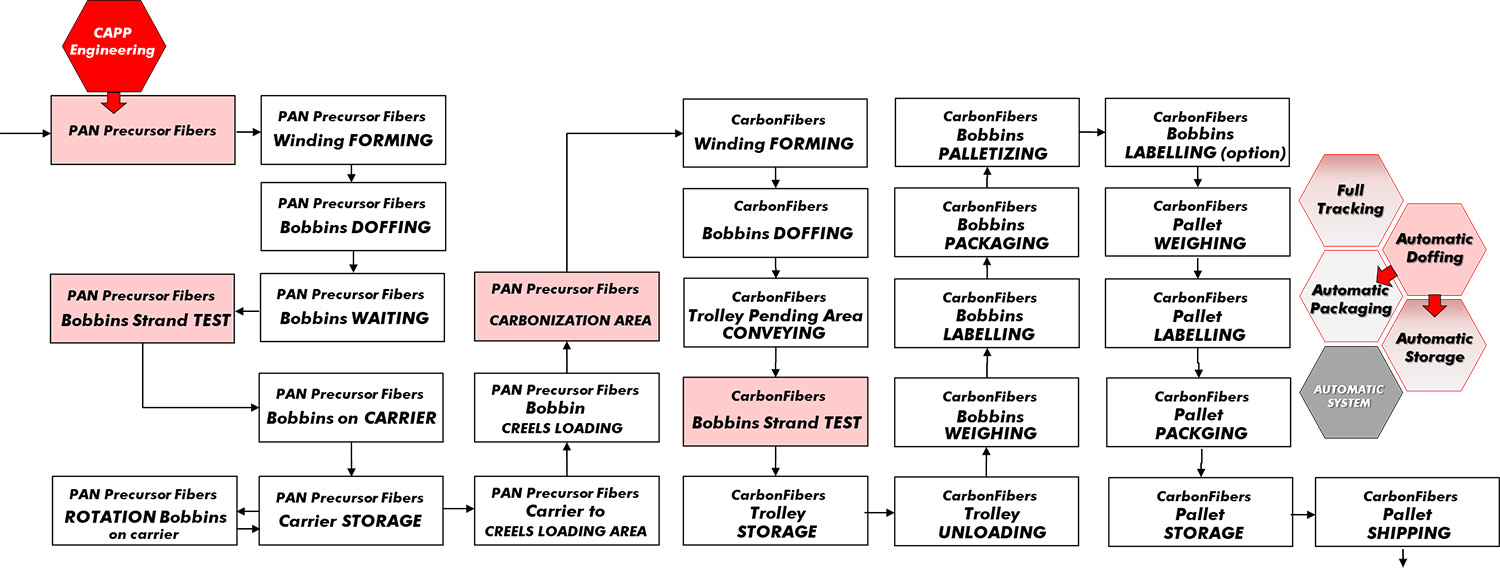

From PAN Precursor Bobbin Doffing Storage and Creels Loading to Carbon Fiber Bobbin Packaging

CAPP Engineering

Manufactures complete, Automatic Handling Lines for:

- BOBBINS STORING

- SORTING

- BOBBINS PACKAGING

- PALLETZING

- PALLET PACKAGING

- PALLET STORING

The modern solution we adopt allows us to reach high quality standards and to reduce the waste.

So our automation is:

- Minimum handling

- The product is untouched and uncontaminated

- Full tracking.

CAPP Engineering

We realize complete automation in the Chemical Fiber fields with full tracking feature.

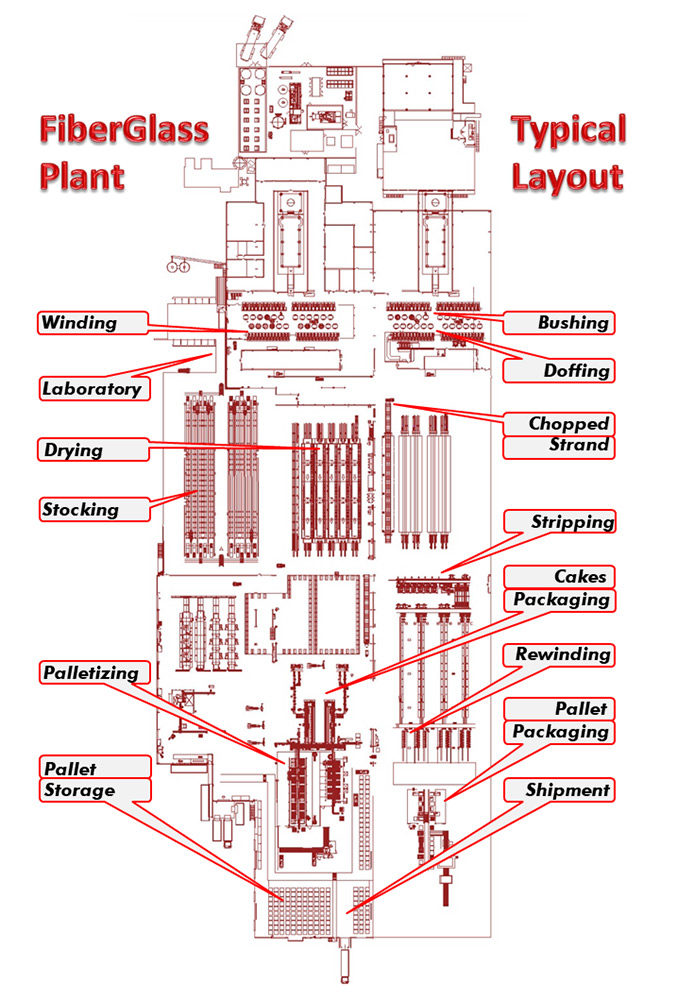

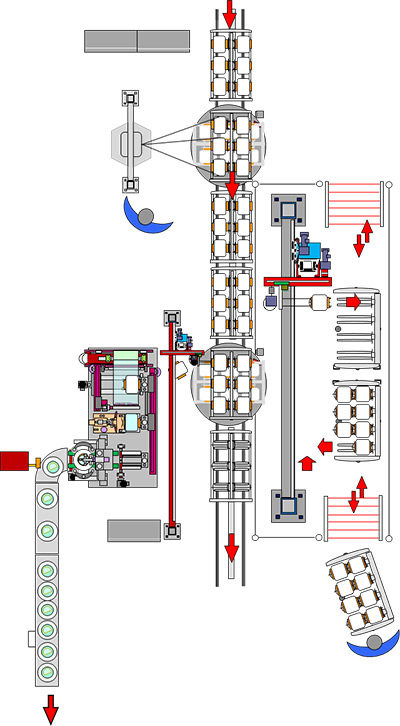

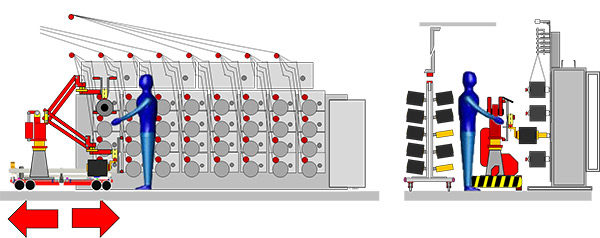

Precursor Bobbin Doffing:

Special Doffer, when bobbins are ready, execute the doffing.

Precursors are placed on special racks with rotating mandrel for the storing process management. Similar machines execute the loading of the creels. The handling of the racks can be realized with the fork lift (up to AGV system).

Interfaces are automatic and the robots can work with operator. Different layout are possible.

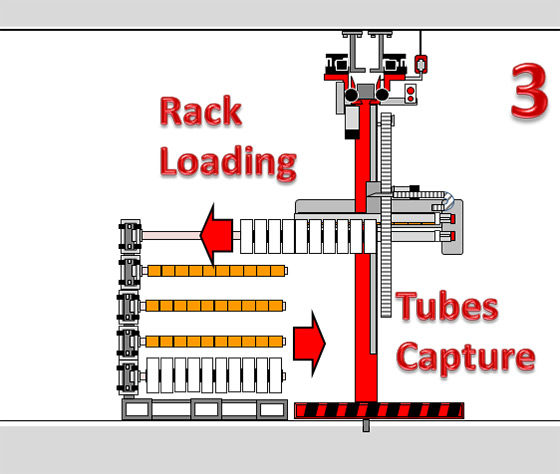

Standard layout: the robot reaches the end of the line unloading the bobbins pack on the pin of the rack. Then it collects the empty tubes and it will be ready to start a new doffing cycle.

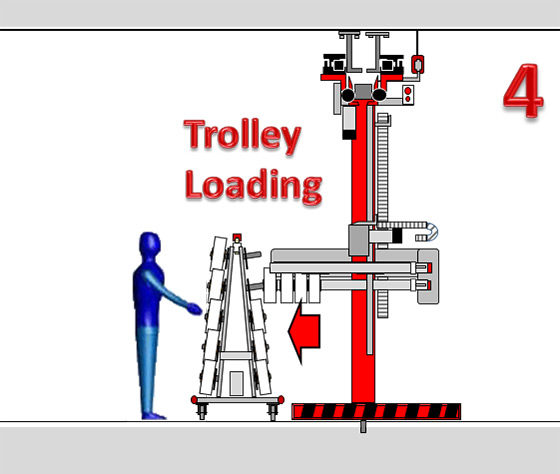

Normally then there is another similar robot that collects the bobbins from the rack and it puts them all on the trolley (in order to singularize them). Trolleys are double-front, so they are placed on turntables in order to let the double faces of the trolley to interface with the robot.

When equipped with a loading tube system, one dispenser placed nearby the trolley is installed.

Carbon Fiber Doffing Area:

In the carbon bobbin winders area, special doff assist can be placed to help the operator in the doffing and in transferring the bobbins on the trolley.

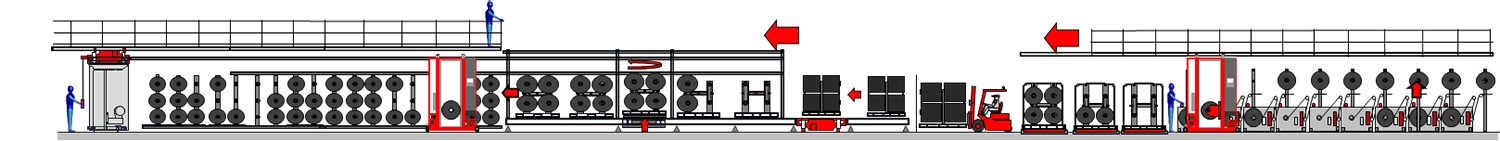

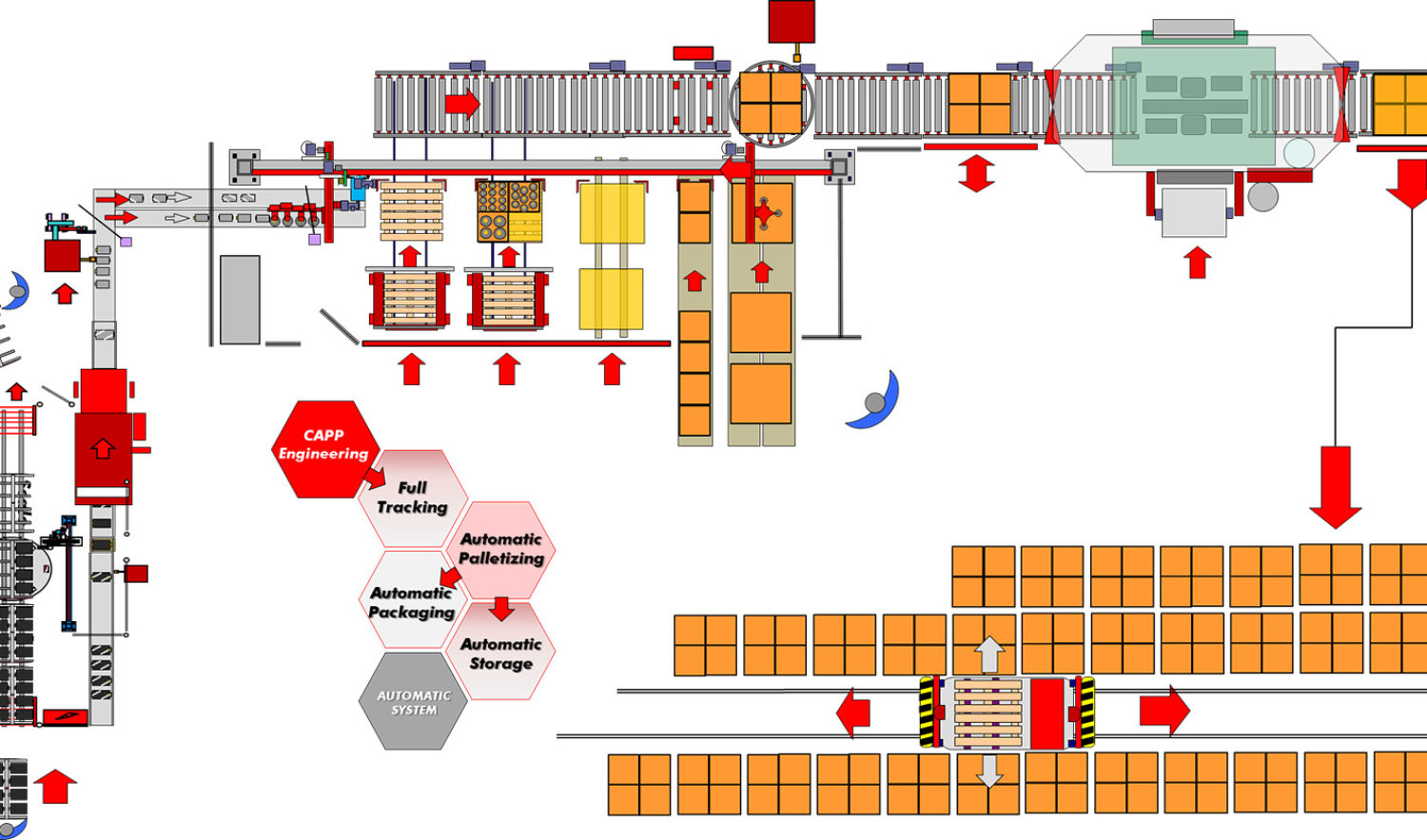

Carbon Fiber Packaging Area:

The trolley are automatically unloaded, the carbon fiber bobbins are sent to the packaging. The bobbins are wrapped by film and then thermo-shrink. The bobbins are automatically palletized in carton box and then pallet packaging.

All these processes include sorting, weighing and labelling. All in full tracking solution.

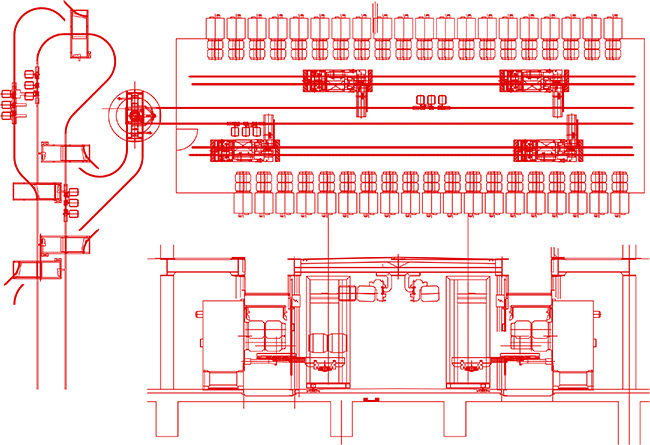

PAN Precursor Doffing, Creel Loading, Carriers

Carbon Fiber Handling Process

Carbon Fiber Doffing, Creel Loading

Carbon Fiber Packaging Typical Layout

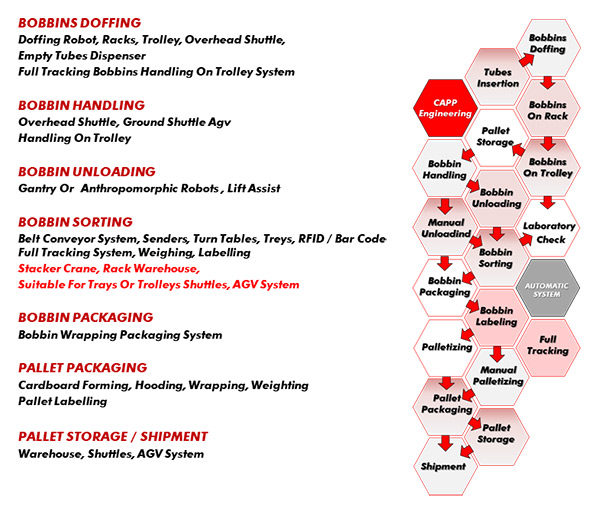

Chemical Fibers (Bobbins POY-FDY-DTY-BCF…)

Bobbins Doffing System

CAPP Engineering

Manufactures complete, Automatic Handling Lines for:

- BOBBINS STORING

- SORTING

- BOBBINS PACKAGING

- PALLETZING

- PALLET PACKAGING

- PALLET STORING

The modern solution we adopt allows us to reach high quality standards and to reduce the waste.

So our automation is:

- Minimum handling

- The product is untouched and uncontaminated

- Full tracking.

CAPP Engineering

We realize complete automation in the Chemical Fiber fields with full tracking feature.

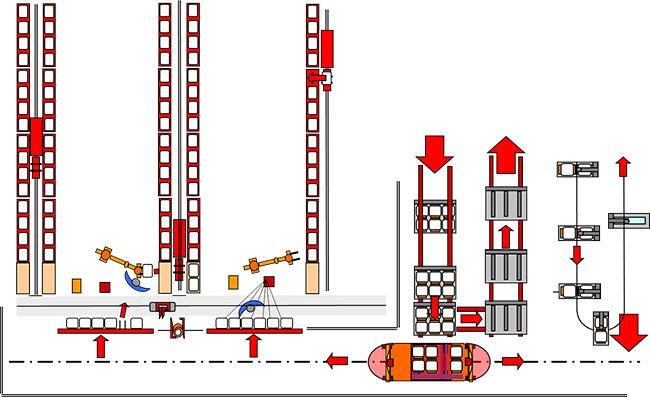

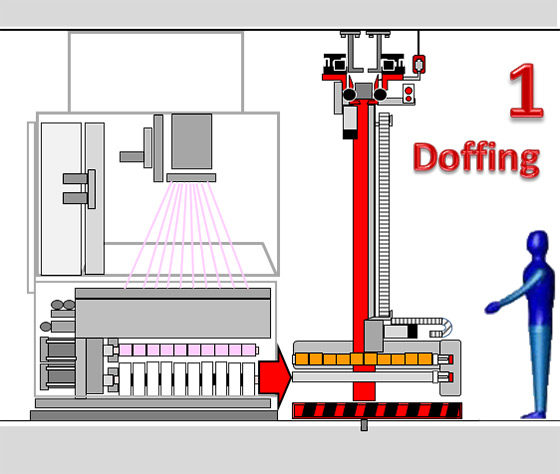

Automatic doffing:

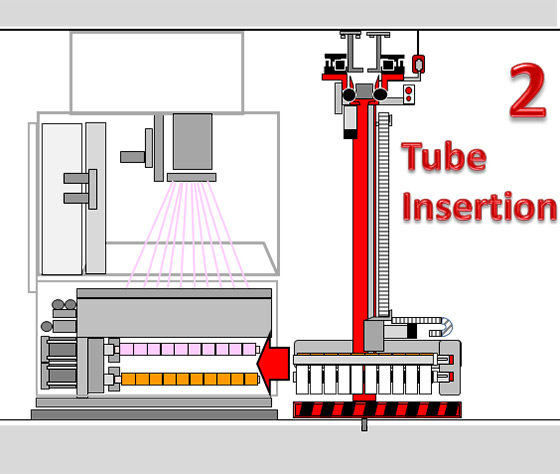

In the winders area special robots, when bobbins are ready, execute the automatic doffing. At the signal "bobbin ready" the Doffer Robot (which is equipped with two mandrels) goes in front of the winder to be served, it doffs the bobbins pack and then it introduces the empty tubes.

Interfaces are automatic and the robots can work with operator. Different layout are possible.

Standard layout: the robot reaches the end of the line unloading the bobbins pack on the pin of the rack. Then it collects the empty tubes and it will be ready to start a new doffing cycle.

Normally then there is another similar robot that collects the bobbins from the rack and it puts them all on the trolley (in order to singularize them). Trolleys are double-front, so they are placed on turntables in order to let the double faces of the trolley to interface with the robot.

When equipped with a loading tube system, one dispenser placed nearby the trolley is installed.

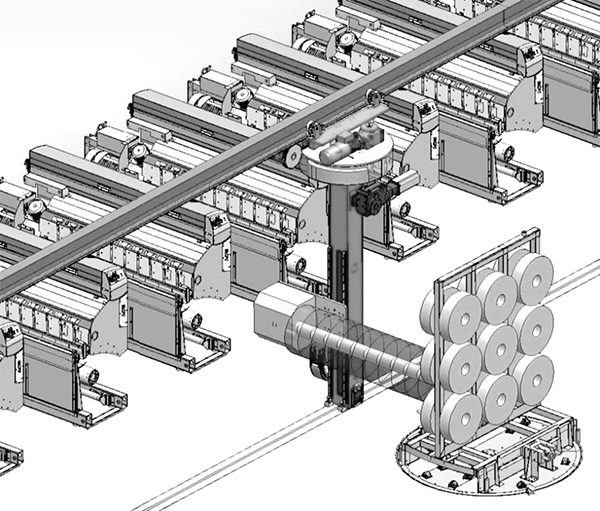

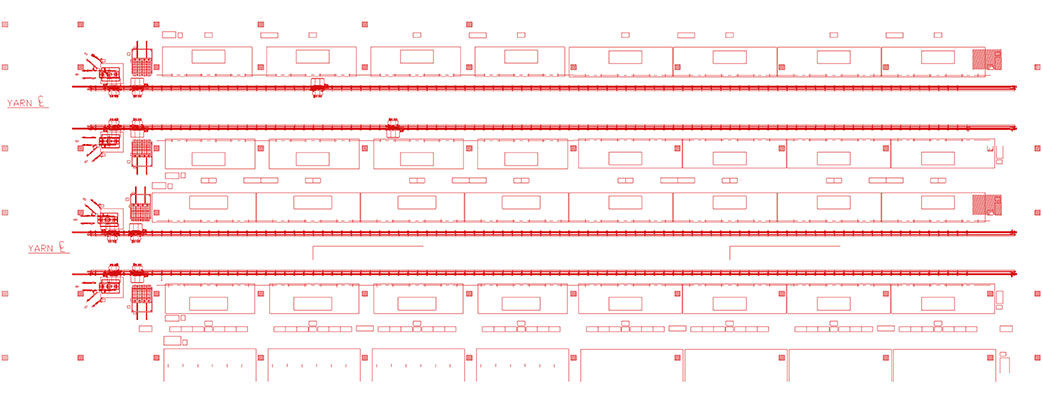

Chemical Fiber Winders Area Typical Layout

Chemical Fiber Packaging Area Typical Layout

Do you have any questions?

Write to us your question and we will get back to you!